Selecting a viable piece of Personal Protective Equipment (PPE) is indispensable for your own safety. Modern prescription safety glasses are built with the most cutting edge technology. However, it is important to know the basics of protective eyewear and their efficacy. Employers incur more $300 million owing to employee eye-injuries at work. This guide intends to help you choose your gear wisely.

- Ascertaining Hazards at the workplace

Experts agree that work injuries can be prevented by 90% with the use of protective eyewear. An apt preliminary action would be to assess the hazards likely to occur at work thoroughly. Predominantly, the number of accidents are caused by the following categories of hazards:

- Toxic Chemicals.

- Ultra Violet Rays – when exposed against bright lights, UV rays can cause damage to the cornea. Tasks involve melting or riveting metals.

- Sharp Objects – includes minute pieces of alloy, ricocheting shards of glass, splinters of wood. Any of these can produce irreversible damage in the eye.

- Eye Injuries caused by instruments at work.

After assessing hazards thoroughly, the next step is to select the lens for your prescription safety glasses.

- Choosing the right lens material

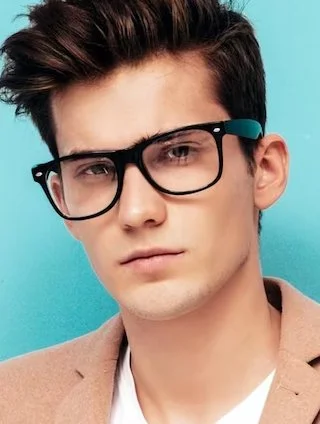

All lenses offer varied benefits & possess their own strengths. Hence, it is imperative to decide about the suitability of your workplace safety needs. One of the most popular lens material is Polycarbonate lens. It offers durability against high-impact accidents. The material is light in weight and highly scratch resistant. It also offers effective immunity against UV rays. It is an excellent choice for workers active in outdoors. It’s quite favorable in contrast to typical glass lens which can gather scratches & is brittle in nature. 3m eagle safety glasses is the industry standard protective eyewear offering guaranteed security.

- Selecting the right lens coating

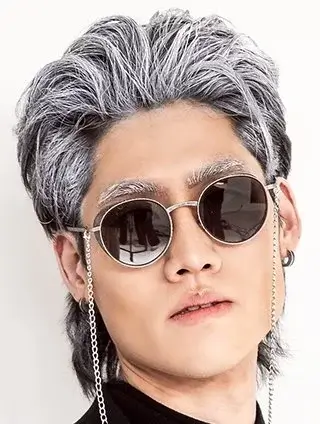

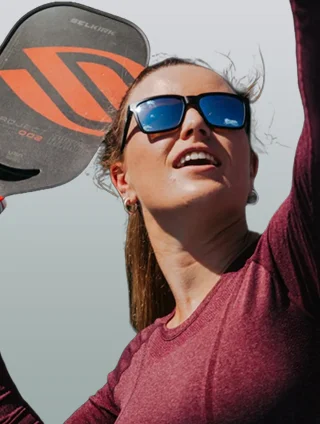

Selecting the right lens coating will supplement the functionality of your eyewear. Lens coating is intended to enhance protection against different prevailing temperatures at work. For instance, Anti-Fog coating prevents the moisture to accumulate on the lens. This prevents the nuisance of taking off and cleaning your glasses. Mirror coating would be a suitable choice for workers engaged in outdoor activities. The very coating helps with reflecting away UV rays from the sun. They prove to be an accurate choice for people working under hot conditions & extended exposure to the sun.

- Ascertaining the eyewear’s standard compliance

Protective eyewear should be certified by the regulatory bodies. American National Standards Institute (ANSI) accords the certification of robustness of eyewear. One should check the ANSI Z87.1 compliance of eyewear. Most eyeglasses would have a permanent etching of “+” on the lens to exhibit their compliance to the standard. It is a fool-proof way to ascertain durability.

- Preventing further accidents

The safety measures do not end with the purchase of a single PPE. Management should regularly confer with the employees on various issues. This includes offering the most comfortable fit before donning the eyeglasses. Extensive training on preventing eye-related injuries is also considered modus operandi.