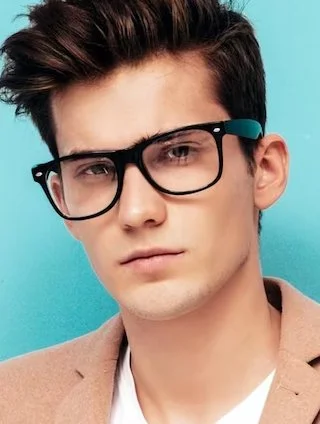

How to Make RX a Safety Glasses?

Working with Rx safety glasses lenses have a similar procedure of shaping and polishing a smooth piece of wood. This is just all the procedure.

Making of Rx safety glasses:

The lenses of safety glasses Rx frames have many stages of handling before ready to send to users. Form taking the lenses to grind for prescription, edging to coat, the5/re is a collection of multiple processes that are carefully finalized in a specific order. Prescription lab for eyes should be equipped with finning and polishing machines, prescription generator, lensmeter, lens tinters, edging, and coating machine. The machinery is continuously regulated, coolant, polish interchanged, and filtered. The lenses are inspected and inspected. The optical lab is like a complex machine that needs higher maintenance to keep it running correctly.

How prescription lenses are made for Rx safety glasses?

- Pull the frame: With the coming of order in the lab, first a frame is pulled and a pair of lenses that are semi-finished from the stock. And then put the order with a detail slip in the tray.

- Your prescription: As your prescription is entered into a lab, computer system and a tracing machine locate the pocket of frame’s lens. The location is saved with the prescription and all employees and machines are informed for making the safety eyewear correctly.

- Block the lenses: Now the step comes of semi-finished lenses where they are blocked. This is the process where a small round tool is fixed in front of the lens in this way that machinery can grasp the lens with a tool. But all this is done without damaging the lenses.

- Generate the prescription: After blocking the lens, a prescription is generated over the lenses. This is the first rough draft when RX prescription safety glasses prescription is generated over the lenses.

- Fining and polishing: In this step, the lenses are moved to finning and polishing. But for this, they have to pass from numerous stages, where a rough prescription is fining again and again. In the end, the last stage is buffing pads and all these things occur in the machine. Here the lens is polished and the lens become so smooth.

- Inspection and coating: After the procedure of fining and polishing, the inspection process is started and then sent out for coating.

- Edging: Now edging process is started and used CNC edging machine that gives the proper shape of the lens according to the frame. The optical center is adjusted according to the shape and size of the frame.

- Tinting and coating: After this procedure, the lenses are inspected again and then sent for tinting and coating.

- Lens insertion and inspection: Finally, the last stage has come and the lenses are inserted into the frame. The lenses are inspected for any defects like prescription error, scratches, and frame equilibrium.

- Packing and shipping: After the final inspection, the lenses are packed and then shipped out to you. Your order for designer glasses online is ready to reach you and try it.

Many times, the lenses are inspected throughout the entire process and if any error is caught, immediately correct that error. In case of any error, possibly discover and repair it in minimum time. Many people work in a lab for making eyewear and therefore the chance of error is rare.