Last updated: Thursday, February 20, 2025

When it comes to the industry standard Personal Protection Equipment, Pentax always gets a notable mention. It has always been the premium brand in the landscape of safety glasses. The company’s omnipresence can be felt by its large stature and overall market share. The variety offered by its unmatched assortment of eyewear boasts both quality & value for money. In the context of providing the best hardware for eye protection, they know how to do it the best. There are a few things to consider that comprise premium protection gear for the eyes.

Durability

Pentax safety glasses are praised for their robustness. The durability comes into play in most of the industries involving activities of cutting, welding & melting. This is common among automotive, morphing metal & pharmaceutical industries and others. There are certain industry standards to adhere to when it comes to providing resistance against high-impact accidents. The compliance standards are laid down by the American National Standards Institute (ANSI) in the US & Canadian Standards Association (CSA) for shipping in Canada. For legit compliance, Consumers must look for a Z87+ mark etched on the lens. The ANSI standard Z87.1-2003 stipulates that eyewear must withstand accidents of high impact. The tests conducted to verify the strength of the material are quite intense. For instance, there is a High-Velocity Impact Test. It consists of the impact of a metal ball traveling at a speed of 150 feet per second from a distance of .25 inches. Most glasses must undergo this before being assembled as a finished product. The lens material is made out of Polycarbonate. It is essentially plastic in physical terms. Polycarbonate is often used to make penetration-proof shields. The Pentax v1000 safety glasses include both frame & lens made out of polycarbonate. The plastic is very scratch-resistant & is less costly to manufacture in contrast to the glass.

Shop Pentax V1000 Safety Glasses

Comfort

Workers are often involved in activities where an inherent risk of the glasses falling off is present. Padding around the temples of glasses allows for comfortable wear through long hours of work. The foam gasket around the lens keeps the glasses from falling off while working. It allows for a more snug fit as well. The part where the glasses rest is also padded for added comfort to the nose bridge. Most of the glasses also provide the option to remove the temples to allow use with an elastic band where needed.

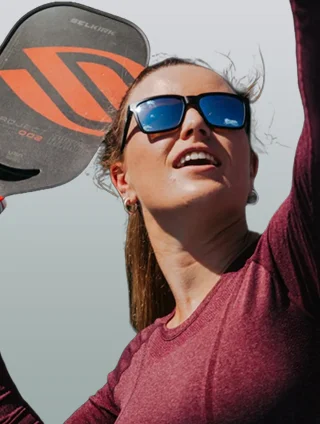

Lens Coating

Safety glasses need to have a certain coating that enables clear vision while working. One example of this is the anti-fog coating. The company’s proprietary “Scotch Gard” coated lens keeps away the condensation. This is important when it comes to working under polarized temperatures. UV protection is also offered by the lens coating under the polycarbonate lens. Most glasses lay a legitimate claim of being impervious to 99% of UV rays. Furthermore, the photochromic lens coating can help acclimate to different lighting conditions. This removes the hassle of switching and donning different glasses.