Industries and some other manufacturing settings are hazardous places for workers. From harmful chemicals to sharp flying particles, it is necessary to keep safe of workers from all kinds of injuries. Thus personal protective safety eyeglasses frames are crucial to provide every worker with eye protection. Personal protective gears contain all safety items from clothing to safety eyewear. Thus, these safety gears are not limited to one industry, but it is the need of every industry.

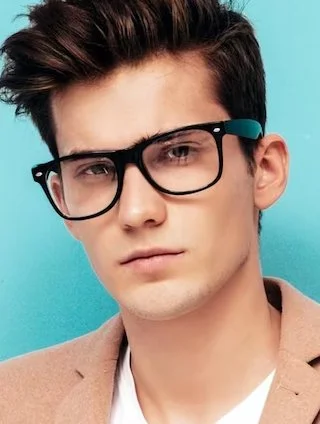

Wiley X Peak | Safety Glasses

Technically, personal protective eyewear is like a physical barrier that prevents workers from dangerous materials and items that can hurt their eyes. Hazardous substances, whether they are in the form of materials or flying objects, can cause damage to the eyes.

Types of Personal Safety Gears for Manufacturing Sectors:

- Safety specs are a physical barrier for the eyes against flying particles and dangerous substances that hurt the eyes during the manufacturing process.

- Breathing masks protect workers from inhaling difficulties like dust and other chemical fumes.

- Headphones are the best source of noise-cancelling and prevent workers from hearing destruction. This is the cause of manufacturing tools creating a loud noise.

- Gloves are also necessary if your workers are handling toxic substances.

- Fall protection is also necessary because harnesses can protect workers from injuries if they fall from height.

Digital Manufacturing and Protection:

No doubt, the safest part for the workers is to stay away from harmful physical situations. Well, it seemed nonsense in the past. But now, the increasing demand for digital technology regarding manufacturing is making a possible lot of impossible things. For example, digital technology has made a gap between workers and danger with fast productivity.

Remote Controlling From Distance:

Through digital solutions in manufacturing, many facilities are discovering how to hold existing infrastructures with instant controls. Thus, they are specific to different actions like machines turning on and off remotely. This is especially helpful in an emergency or even can be used during maintenance. Such functions are suitable when faulty machines could be dangerous for the workers if they want to handle them manually. Furthermore, if machines have arms or other heavy equipment, it would be more convenient to control them remotely. Remote handling is a safe process rather than the workers operating all functions at a certain height which can lead to a threat of injuries.

Add More Automation:

Due to the manufacturing process being facilitated by digital transformation, more industries are producing programming tasks in manufacturing lines. Thus automation is not only improving consistency, productivity, and cost-effectiveness. But it is the best strategy to increase protection for workers in the factory area.

By applying digital technology in the manufacturing process, you can easily access sensitive data to check the performance of the equipment. Besides, it can show any defect in advance before hurting any worker. Furthermore, you have the option to adjust safety equipment shut down or stop any object or any person close to the machine. With an automated process, more workers shifted to monitoring roles. Ultimately, an automatic process will reduce dangerous exposure.

Importance of Safety Eyeglasses for Manufacturing Places:

For those people who don’t consider the importance of eye safety, they should reconsider it. Because more than half of injuries occur at the workplace due to not wearing appropriate safety eyeglasses frames every time during accident time. Accidents can also occur due to not wearing the right protection. Surprisingly, more than $300 million annually including medical expenses, employer compensation, and missing production time.

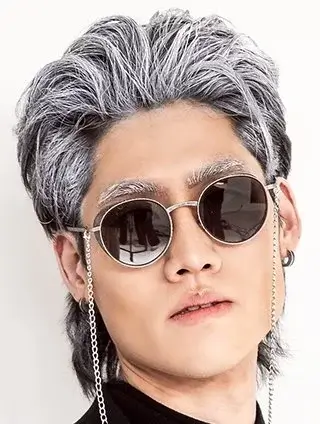

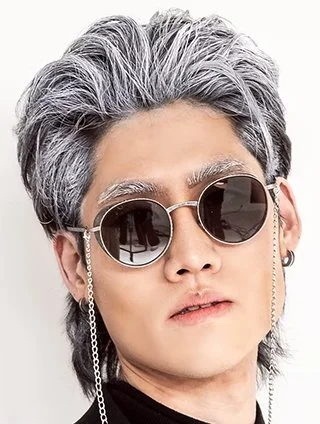

Pentax F9800 | Safety Glasses

These shocking figures show that eyes are necessary for workers by manufacturing controls and personal safety gear like safety goggles, face shields, and safety glasses. Most eye injuries occur at workplaces due to the striking of small particles in the eyes. Some statistics indicate that over 70% of eye injuries result from objects falling into the eye. Even injured workers said that most of the hazardous particles were too small as a pinhead.

Eye injuries also occur due to the striking of metal, staples, or nails penetrating the eyes. These penetrations even lead to severe harm like permanent vision loss. Blunt traumas are also another cause of eye injuries like chemical burning from the splashing of cleaning or chemical products. Welders are close to the threat of thermal burns and ultraviolet radiation hurt from a flash.

Eye Injuries in Different Professions and Vital Safety Glasses:

According to occupational statistics, craft employers have a maximum ratio of eye injuries. On the other hand, plumbers, pipefitters, and electricians are also top traders with the highest eye injury rate. Keep remembering different hazards need appropriate protection. Therefore, workers should assess their eye protection before buying work safety glasses.

- The nature of hazards needs the right requirements as applicable.

- Environmental exposure

- Other uses of safety equipment

- Personal vision requirement

Eye safety must join with other personal protective gear to access maximum safety from head to toe. Besides, it should be an excellent fit for an individual employer or deliver enough coverage. According to some surveys, more than 90% of eye injuries are preventable by wearing appropriate safety eyes against chemical droplets around workplaces. Safety specs should be enough comfy and provide adequate peripheral vision.

Comfort and Style Allow Compliance Safety Glasses:

Safety glasses should be comfortable and provide adequate protection. Besides, many types of research have proved that the style and comfort of eyeglasses motivate workers to wear safety glasses. Keep remembering protective eyewear cannot shield eyes if you store them on the shelf or overhead.

Thus it is necessary to wear safety eyewear, and it should be adequately comfy for a worker. So that workers can wear safety specs for several hours if needed. Comfortable features include vented frames, nose bridges, flexible temples, cushioned brows, and lenses that should have adjustable shades.

Comfort is also extendable with other features to avoid fogging if you are using a certain respirator. For performing these tasks, you need to look at protective glasses that can protect against particles and fog shields. Safety frames should have foam around them for additional safety.

Wearing fashionable eyeglasses with stylish features can also motivate workers to wear safety glasses. For example, wraparound style eyeglasses, mirror lenses, and bold style can attract workers to wear them. Basically, this is the chief cause that can attract manufacturers to wear fashion-forward eyeglasses.

Today safety gears allow employers to enhance their personality with the best compliance. The availability of safety gear in several options regarding styles and colours allows workers to look smarter. When manufacturers are satisfied with their looks with safety glasses, they would like to wear them regularly.

Cool factor has more attraction for workers at the working place. But be careful that style shouldn’t lower the function. All protection products should offer significant protective features like distortion-free and impact-resistant lenses. Make sure the safety eyeglasses are ANSI Z87.1 certified and deliver ultimate safety from dangerous UV radiation.

Keep remembering that safety specs shouldn’t be designed with glass or plastic lenses that are not sufficient to stand against impact conditions. Therefore, avoid using these safety glasses while working among the debris. Otherwise, cover your eyes with safety goggles. Polycarbonate lenses are designed for impact situations. They are more lightweight and impact-resistant than other materials. But buy polycarbonate lenses with a scratch-resistant coating to prevent them from scratching.

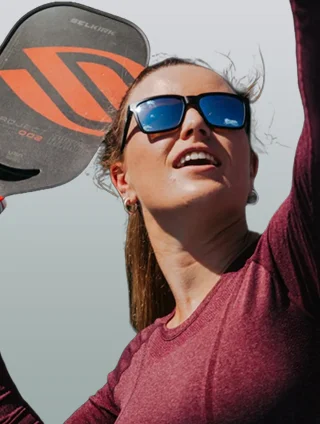

ArmourX 6002 | Safety Glasses

Train User for Personal Protective Eyeglasses Use:

Deliver enough training to the wearers who need the best protection for their eyes and face. This is essential for workers to ensure workplace safety, and workers can easily prevent injuries. Many people get injured due to not using safety specs or wearing inappropriate protection in the workplace. According to one survey, more than 40% of people had no idea where to use safety specs and for what purpose.

Protection policies should be adequately clear and advise them with the following chief points while communicating with workers.

- When to use protective eyewear

- What is the entire enforcement method?

- From where workers can access quality safety glasses

- How do replace safety glasses in case of any defect?

- What is the exact way if eye safety is missing in the workplace?

It is the responsibility of the workers to take the best care of the safety specs and prevent them from scratching. Place safety glasses in the proper place when they are not performing any tasks. Protective glasses should be placed in dry and dust-proof places when don’t need them. Dirty and scratched specs block clear vision, lead to glare, and even contribute to accidents. Immediately replace safety glasses that are scratched or lost because they are more dangerous for work safety.

Long-Term Issues With Minor Injuries:

A minor eye injury can sometimes lead to permanent vision loss, and even you can be disabled from work. For example, dust particles, wooden, sand, or metal chips can hurt the eyes and even lead to pain cornea. Thus, more than 90% of eye injuries are preventable due to using appropriate safety specs.

Summary:

When accidents happen there is a long chain of incidents with chief concerns. Work-related eye injuries affect work, medical expenses, cost of workers, and production. Thus educate your workers about possible hazards at manufacturing places. Practice workers for a safe workplace and motivate them to wear safety eyeglasses frames to reduce injuries. Always give employers first-class safety specs if they are working in dangerous sectors.